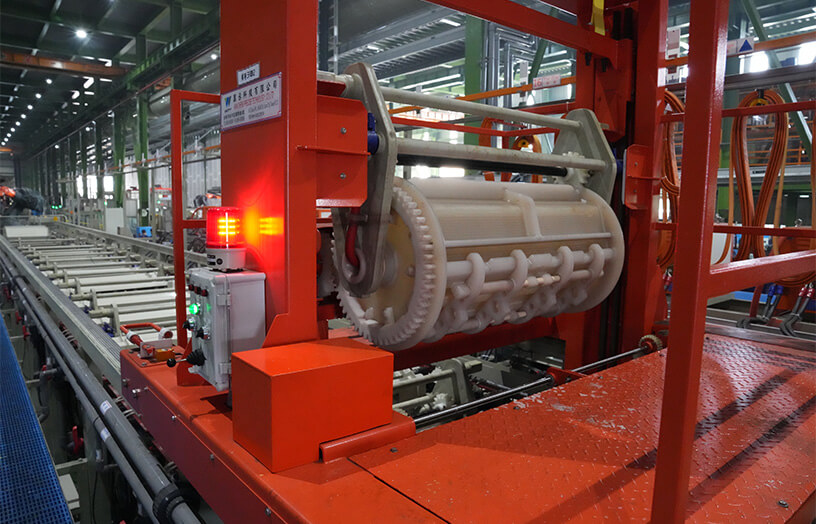

barrel type

Barrel type surface treatment equipment can be designed as either straight-through or U-shaped according to the customer's conditions. Automated controls can also improve product quality and stability.

- Suitable Process

- acid/alkaline zinc plating, phosphate, polishing and zinc-nickel alloy plating, etc.

- Suitable Workpieces

- screws, nuts, general hardware, zippers, electronic components and passive parts, etc.

- Features

-

- Can achieve cleaning and surface treatment processes.

- Various types of barrels are available for selection based on production needs and workpiece conditions.

feature

- octagonal design

- Enhance the rolling ability of the workpiece in the barrel

- material

- Imported from Germany, the P.P. (polypropylene) is resistant to high temperatures and acid-alkaline substances.

- barrel reinforcemen

- Covering the SS400 with P.P. plate extends the service life of the barrel.

- barrel holder

- Covering aluminum with P.P. provides greater durability, reduces the weight of the barrel, and makes it more rugged.

- holes design

- Matching different drilling sizes and shapes with workpieces improves the exchange rate of plating solutions, avoids material blockages, increases plating efficiency, and ensures even thickness.